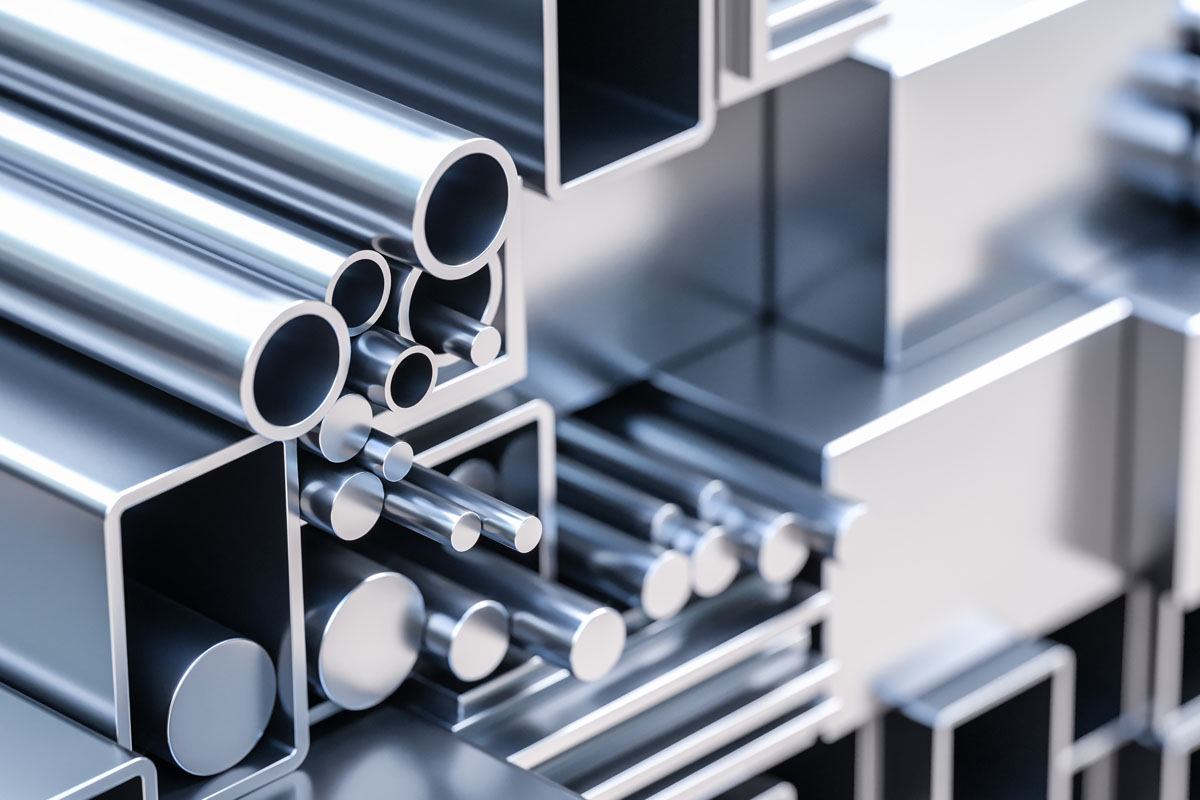

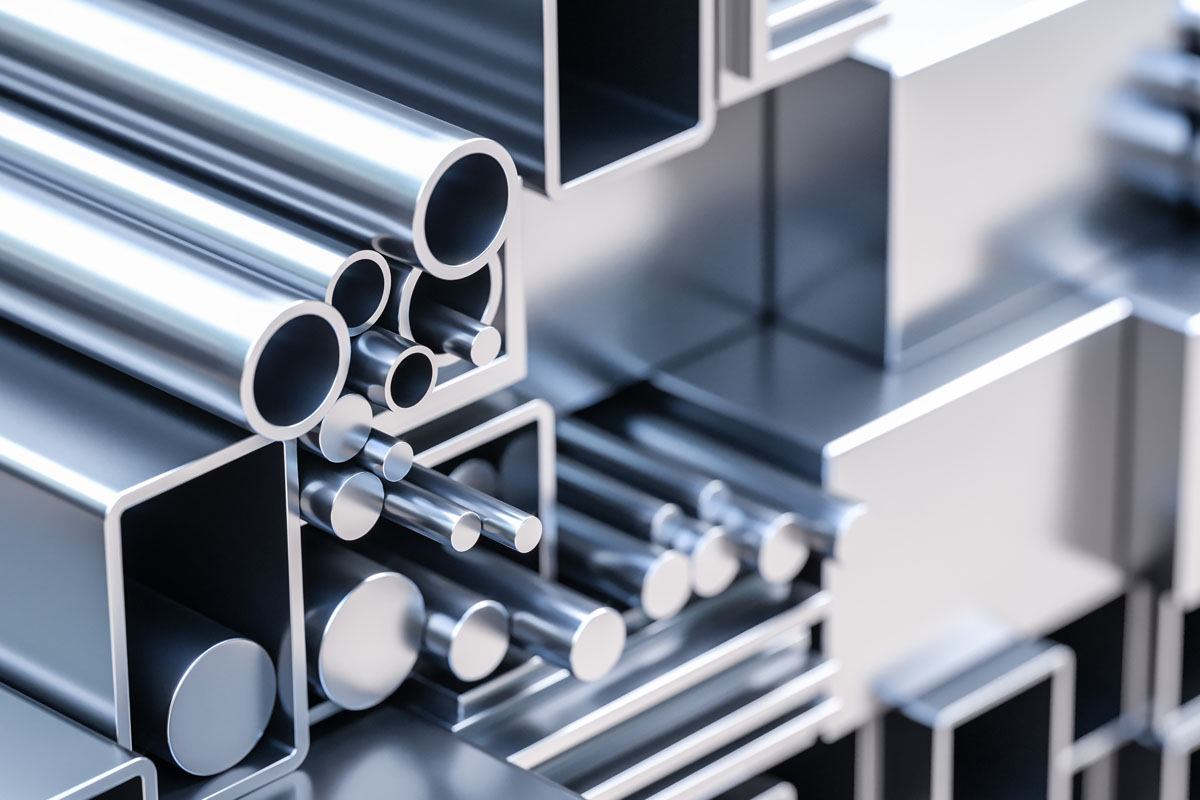

Aluminum is a lightweight metal material widely used in industry and construction. Among them, 6063 and 6061 are two common aluminum alloy materials. They have some significant differences in chemical composition, physical properties and areas of application. In this article, we will compare these two aluminum materials and discuss which one is better. First, let's understand the chemical composition of these two aluminum materials. 6063 aluminum alloy is mainly composed of aluminum, silicon and magnesium. It has a high silicon content, which improves the material's fluidity and malleability. In contrast, 6061 aluminum alloy contains a higher percentage of aluminum, magnesium and silicon. It has a higher magnesium content, resulting in better strength and hardness. This difference has some important implications in terms of physical properties. Aluminum 6063 has good machinability and is easy to cut, weld and form. It has high corrosion resistance and excellent wear resistance. This makes 6063 aluminum alloy ideal for use in Architectural Aluminium Profiles, such as Aluminum profiles for doors and windows, Decoration Furniture Aluminium Profile. It also has good bending properties, making it suitable for making complex shaped parts. However, due to its relatively low strength, 6063 aluminum alloy may not be strong enough for applications that need to withstand high pressure and heavy loads. In contrast, 6061 aluminum alloy has higher strength and hardness. It has excellent mechanical properties and can withstand higher pressures and heavy loads. This makes 6061 aluminum alloy widely used in aerospace, automotive industry, Industrial Aluminium Profile and sports equipment. However, due to its high hardness, 6061 aluminum alloy has relatively poor machinability. It is more difficult to cut and form than 6063 aluminum alloy, requiring higher process requirements and costs. In summary, there are significant differences in the chemical composition and physical properties of 6063 and 6061 aluminum materials. 6063 aluminum alloy is suitable for those applications that require high machinability, such as interior decoration and architectural window and door frames. It has good corrosion resistance and malleability. In contrast, 6061 aluminum alloy is used in applications that require high strength and hardness, such as the aerospace and automotive industries. It has excellent mechanical properties but poor machinability. However, determining which aluminum material is better needs to be evaluated based on the specific needs of the application. If machinability and malleability are primary considerations, then choosing 6063 aluminum alloy may be more appropriate. If strength and hardness are the primary concerns, then choosing 6061 aluminum alloy may be more appropriate. Therefore, when choosing an aluminum material, trade-offs and trade-offs should be made based on specific application needs and particular performance requirements. In summary, the aluminum materials 6063 and 6061 differ in chemical composition and physical properties. 6063 is suitable for applications that require high machinability and malleability, such as interior decoration; 6061 is suitable for applications that require high strength and hardness, such as aerospace. The choice of which aluminum material to use should be evaluated based on specific needs and performance requirements.